Pressure induced phase transformations in an additively manufactured alloy

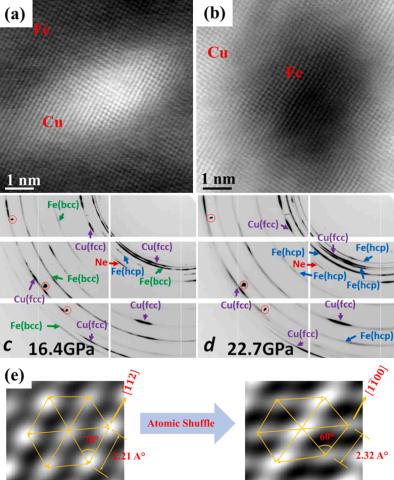

Improvement of alloys opens fundamentally new technical opportunities. Additive manufacturing is a powerful tool to make finely tuned alloys with tailored, previously unattainable combinations of properties. Application of high pressure puts the materials under a great deal of strain, and potentially reveals unexpected combinations of plastic, elastic deformations and atomic rearrangements. Researchers from University of Michigan, LLNL and ANL used the U.S. Department of Energy's Advanced Photon Source to look at an alloy of copper (Cu) and iron (Fe) under extremely high pressures. Their results are published in the journal Acta Materialia. The team used laser directed energy deposition to make Fe67Cu33 alloy (nominal composition in at. %), which is distinguished by its hierarchical microstructure. Phase transformations and structural stability of this alloy were investigated under high static pressure deformation using in-situ synchrotron X-ray diffraction under pressure, postmortem high-resolution scanning transmission electron microscopy, and molecular dynamics (MD) simulations. Metastable coherent precipitates of both Cu and Fe have been clearly observed with electron microscopy (Fig. 1a, b). In-situ XRD results reveal a reversible phase transformation from body-centered cubic (BCC) to the hexagonal close-packed (HCP) structure in the Fe grains at an onset pressure of 16.4 GPa, significantly higher than reported in the literature for pure Fe (Fig. 1c, d). High-resolution scanning transmission electron microscopy analysis uncovers a phase transition to the HCP structure in nanoscale metastable BCC Cu precipitates within the BCC Fe matrix (Fig. 1e). This transition, consistent with the classical Burgers mechanism, is directly supported by MD simulations.

For more, see: Daniel Yin, Bibhu Prasad Sahu, Phillip Tsurkan, Dmitry Popov, Avinash M. Dongare, Nenad Velisavljevic, Amit Misra,

High-pressure phase transitions in a laser directed energy deposited Fe-33Cu Alloy, Acta Materialia, Volume 268, 2024, 119797, https://doi.org/10.1016/j.actamat.2024.119797